Laser Gold plating reflectivity is greater than 99% at 10.6 microns and greater than 97% at 0.7 microns when measured on a low-scatter substrate, measured at 6 degrees angle of incidence. The reflectivity in the infrared equals and often exceeds that of a freshly vapor-deposited gold. Because of its outstanding cleanability, stability and reflectivity, in 1984, the National Bureau of Standards, (NIST), chose Laser Gold plating as the Standard IR reference material (#2011). For more than twenty years, Epner Technology had been the sole source supplier of these standards.

Becoming the Gold Standard of Gold Standards

I was indeed flattered when Leonard Hanssen of NIST requested us to supply a quantity of twenty-five specular mirrors coated with Laser Gold, and the same quantity of diffuse substrates that he would supply, on which we would do the Laser Gold plating.

Our mirrors were diamond turned copper blanks supplied by Kugler of Salem, Germany, while the NIST blanks were roughened by arc-spraying aluminum on a machined brass substrate.

The Epner mirrors were two samples, of a five sample group that was individually calibrated at NIST and then sent to twenty-three participating optical laboratories in a groundbreaking nationwide “Star” Intercomparison of Infrared Reflectivity, with each lab getting its own separate sample set.

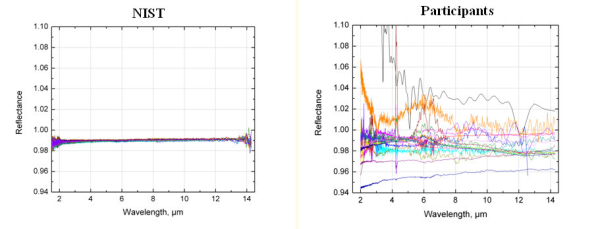

Incredibly, the Epner Technology specular mirrors, when calibrated by NIST prior to their distribution to the participating labs, all tracked at 99 percent with each mirror creating a single flatline on the graph! (see Fig.1)

Fig. 1

Our rough, diffuse Laser Gold coated samples showed similar consistency when measured by NIST for the pre-comparison data points. (see Fig. 2)

Fig. 2

While the measurments of the specular sample from a few of the 23 participants ranged from 94% to 102%, according to Leonard Hanssen and Boris Wilthan, Directors of the study, the overall comparison results were “encouraging.”

To obtain the complete report of this unprecedented study, including the list of the 23 participants, the stucture and analysis of the results, including all the graphs, click below (All this makes for a large file [9.95MB], so be patient!).

- Laser Gold Spectral Reflectance Graphical Data

-

This reflectance chart depicts measurements made by three separate organizations, China Lake Naval Weapons Center, (measurement made under the renowned Jean Bennett), Hughes Aircraft’s Optics Lab, then in Culver City, Ca. and AZ Technology, a NASA source in Huntsville. In all cases, the measurements were made with the Laser Gold plated over a highly polished, low scatter electroless nickel substrate. At 700nm wavelength reflectivity is an astounding 97% and >99% @10 microns. Measured at 6 degrees angle of incidence.

Read More

- Laser Gold Spectral Reflectance Tabular Data

- By AZ TECHNOLOGY

- Hemispherical Reflectance of Laser Gold

- The first test of the coating was to determine the solar absorptance and the directional hemispherical spectral reflectance from 250nm-2800nm. AZ Technology specifically designed and built the Laboratory Portable SpectroReflectometer (LPSR-200IR) to perform such measurements. The LPSR-200IR measures the directional hemispherical spectral reflectance of the sample at 100 wavelengths in less than two minutes from 250nm-2800nm and from this data calculates the solar absorptance.

Read More - By AZ TECHNOLOGY

- Hemispherical Directional Reflectance on Specular Au

- Phi_i Orientation: 0.0ºData Points: 191Spectral Range: 500 to 2500 nanometersReflectance Units: % Reflectance Data Type: Hemispherical Directional Reflectance General Description: Specular Au (Epner Sample #2) Unpolarized

Read More - By Surface Optics Corporation

- Specular Gold Directional Reflectance at 20 Degrees Incidence

- Wavelength: 400 – 2600 nanometers

Read More - By Surface Optics Corporation

- IMR Laser Gold Test Report

- At IMR Test Labs in Lansing, NY, six samples were tested, three from Epner Technology, Inc. and three samples from an unidentified competitor (provided by L3 Communications), calculating the Hemispherical Directional Reflectance measurements. The samples were sent out, first to be environmentally tested in a humidity chamber (exposed to 120°F at 95% for 24 hours), then sent back out for reflectivity testing.

Read More - By IMR Test Labs

- Spectroscopic Ellipsometry Analysis of Opaque Gold Film

- Ron Synowicki, with J.A. Woollam, Co., Inc., measured the optical n & k properties of our Laser Gold plating using spectroscopic ellipsometry.

Read More